Categories

New products

-

Lens Ring Joint Gasket

If you are willing to import customized and good quality high lumen Lens Ring Joint Gasket from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Lens Ring Joint Gasket price and quotation with a such exporter, providing with Lens Ring Joint Gasket enquiry, welcome to contact us.

-

Double Jacket Gasket

If you are willing to import customized and good quality high lumen Double Jacket Gasket from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Double Jacket Gasket price and quotation with a such exporter, providing with Double Jacket Gasket enquiry, welcome to contact us.

-

Corrugated Gaskets

If you are willing to import customized and good quality high lumen Corrugated Gaskets from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Corrugated Gaskets price and quotation with a such exporter, providing with Corrugated Gaskets enquiry, welcome to contact us.

-

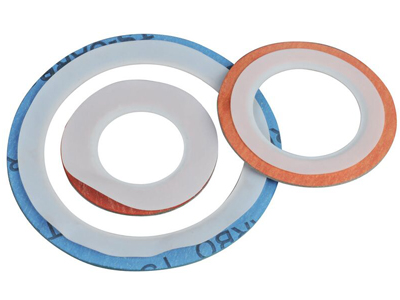

PTFE Envelope Gasket

If you are willing to import customized and good quality high lumen PTFE Envelope Gasket from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM PTFE Envelope Gasket price and quotation with a such exporter, providing with PTFE Envelope Gasket enquiry, welcome to contact us.

-

Rubber Sheet

If you are willing to import customized and good quality high lumen Rubber Sheet from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Rubber Sheet price and quotation with a such exporter, providing with Rubber Sheet enquiry, welcome to contact us.

Non-asbestos Rubber Gasket

Synthetic Fiber gasket cut from Synthetic Fiber rubber sheet. Suitable for use as an oil-resistant jointing medium for heat installations and engine sealing

| Non-asbestos Series | MPTFE Series |

|

Kaxite? line offers a variety of elastomers to excel in a wide range of services. |

Modified PTFE line offers good resistance to cold flow (creep), high pressure service, and good chemical compatibility. |

KXT? Style 2200

Style 2000

Aramid fibers with a nitrile binder.

Benefits

Excellent sealability

? Unique blend of aramid fibers, fillers and a nitrile rubber binder provides improved torque retention and drastically lowered emissions levels

Cost savings

? Cuts operational costs through reduced:- Waste- Waste- Maintenance- Stocked inventory- Fluid loss- Energy consumption

Media

? Water

? Aliphatic hydrocarbons

? Oils

? Gasoline

| KXT 2000 Specifications | |

| Min. Temperature: | -100oF |

| Max Temperature: | 400oF |

| Min. Pressure: | 1000 (PSI) |

| Maximum PxT 1/16: | 350,000 (oF x PSIG) |

| Maximum PxT 1/8: | 250,000 (oF x PSIG) |

KXT? Style 2200

Style 2200

Aramid fibers with a nitrile binder.

Benefits

Excellent sealability

? Unique blend of aramid fibers, fillers and a nitrile rubber binder provides improved torque retention and drastically lowered emissions levels

Cost savings

? Cuts operational costs through reduced:- Waste- Waste- Maintenance- Stocked inventory- Fluid loss- Energy consumption

Media

? Water

? Saturated steam

? Inert gases (meets MIL-G-24696B)

| KXT 2200 Specifications | |

| Min. Temperature: | -100oF |

| Max Temperature: | 400oF |

| Min. Pressure: | 1200 (PSI) |

| Maximum PxT 1/16: | 350,000 (oF x PSIG) |

| Maximum PxT 1/8: | 250,000 (oF x PSIG) |

KXT? Style 2300

Style 2300

Aramid fibers with a neoprene binder.

Benefits

Excellent sealability

? Unique blend of aramid fibers, fillers and a SBR rubber binder provides improved torque retention and drastically lowered emissions levels

Cost savings

? Cuts operational costs through reduced: - Waste- Waste- Maintenance- Stocked inventory- Fluid loss- Energy consumption

Media

? Water

? Saturated steam

? Refrigerants

? Oils

? Fuels

| KXT 2300 Specifications | |

| Min. Temperature: | -100oF |

| Max Temperature: | 400oF |

| Min. Pressure: | 1200 (PSI) |

| Maximum PxT 1/16: | 350,000 (oF x PSIG) |

| Maximum PxT 1/8: | 250,000 (oF x PSIG) |

MPTFE? Style 2504

Style 2504 Blue

PTFE with glass microspheres.

Benefits

Tighter Seal

? Improved performance over conventional PTFE

? Reduced product loss and emissions

Reduced creep relaxation

? Unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE sheets

? Excellent bolt torque retention

Chemical resistance

? Withstands a wide range of chemicals for extended service life in a wide variety of applications

Cost savings

? Cuts operational costs through reduced:- Fluid loss- Energy consumption- Maintenance costs- Inventory costs- Waste

Largest sheet sizes

? Offers some of the largest sheet sizes in the industry

? Improved material utilization reduces waste

Branding and color coding

? Easy identification of superior MPTFE? products

? Reduces misapplication and use of unauthorized, inferior substitutes

Media

? Moderate concentrations of acids and some caustics

? Hydrocarbons

? Solvents

? Water

? Refrigerants

? Cryogenics, hydrogen peroxide

| MPTFE 2504 Specifications | |

| Min. Temperature: | -450oF |

| Max Temperature: | 500oF |

| Min. Pressure: | 800 (PSI) |

| Maximum PxT 1/16: | 350,000 (oF x PSIG) |

| Maximum PxT 1/8: | 250,000 (oF x PSIG) |

MPTFE? Style 2510

Style 2510 Off-White

PTFE with barium sulfate filler.

Benefits

Tighter Seal

? Improved performance over conventional PTFE

? Reduced product loss and emissions

Reduced creep relaxation

? Unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE sheets

? Excellent bolt torque retention

Chemical resistance

? Withstands a wide range of chemicals for extended service life in a wide variety of applications

Cost savings

? Cuts operational costs through reduced:- Fluid loss- Energy consumption- Maintenance costs- Inventory costs- Waste

Largest sheet sizes

? Offers some of the largest sheet sizes in the industry

? Improved material utilization reduces waste

Branding and color coding

? Easy identification of superior MPTFE? products

? Reduces misapplication and use of unauthorized, inferior substitutes

Media

? Strong caustics

? Moderate acids

? Chlorine

? Gases

? Water

? Steam

? Hydrocarbons

? Cryogenics and aluminum fluoride

| MPTFE 2510 Specifications | |

| Min. Temperature: | -450oF |

| Max Temperature: | 500oF |

| Min. Pressure: | 1200 (PSI) |

| Maximum PxT 1/16: | 350,000 (oF x PSIG) |

| Maximum PxT 1/8: | 250,000 (oF x PSIG) |

MPTFE? Style 2545

Style 2545

PTFE Gasketing with aluminosilicate microspheres

Benefits

Tighter Seal

? Highly compressible PTFE outer layers seal under low bolt load-suitable for many non-metallic flanges

? Compressible layers conform to surface irregularities, especially on warped, pitted or scratched flanges

? Rigid PTFE core reduces cold flow and creep normally associated with conventional PTFE gaskets

Excellent chemical compatibility

? Pure PTFE withstands a wide range of chemicals

Easy to cut and install

? Soft PTFE can be cut easily from larger sheets, reducing inventory costs and expensive downtime

? Rigid PTFE core facilitates installation, especially on large diameter flanges and hard-to-reach areas

Media

? Strong caustics

? Strong caustics

? Strong acids

? Hydrocarbons

? Chlorine

? Cryogenics

? Glasslined equipment

? Plastic piping

? Low bolt load applications

| MPTFE 2545 Specifications | |

| Min. Temperature: | -450oF |

| Max Temperature: | 500oF |

| Min. Pressure: | 1200 (PSI) |

| Maximum PxT 1/16: | 350,000 (oF x PSIG) |

| Maximum PxT 1/8: |

250,000 (oF x PSIG) |

.jpg)