Categories

New products

-

Lens Ring Joint Gasket

If you are willing to import customized and good quality high lumen Lens Ring Joint Gasket from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Lens Ring Joint Gasket price and quotation with a such exporter, providing with Lens Ring Joint Gasket enquiry, welcome to contact us.

-

Double Jacket Gasket

If you are willing to import customized and good quality high lumen Double Jacket Gasket from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Double Jacket Gasket price and quotation with a such exporter, providing with Double Jacket Gasket enquiry, welcome to contact us.

-

Corrugated Gaskets

If you are willing to import customized and good quality high lumen Corrugated Gaskets from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Corrugated Gaskets price and quotation with a such exporter, providing with Corrugated Gaskets enquiry, welcome to contact us.

-

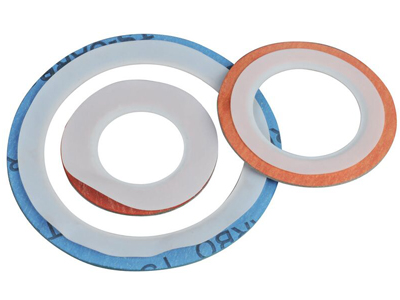

PTFE Envelope Gasket

If you are willing to import customized and good quality high lumen PTFE Envelope Gasket from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM PTFE Envelope Gasket price and quotation with a such exporter, providing with PTFE Envelope Gasket enquiry, welcome to contact us.

-

Rubber Sheet

If you are willing to import customized and good quality high lumen Rubber Sheet from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Rubber Sheet price and quotation with a such exporter, providing with Rubber Sheet enquiry, welcome to contact us.

PTFE Packing with Kynol Fiber Corners

Braided from KynolTM fiber and PTFE fiber. It contains the advantage both PTFE and kynol. It has good strength and lubricates.

Typical Application

>Suited well where graphite impregnation not be acceptable

> For abrasive media, and where contamination is not permitted

> Chemical plants and pulp and paper mills

> Rotating and reciprocating pumps, washer journals, liquor pumps, refiners etc.

Prime Features

> Clean packing

> High pressure conditions than using pure PTFE packings

Technical Data

| Material | 100% Kynol fiber and PTFE | |

| Temperature Range | -200 up to +260 oC atmosphere; | |

| Process | Rotating | 20 bar |

| Reciprocating | 100 bar | |

| Static | 200 bar | |

| Shaft Speed | 20m/s in rotary | |

| PH | 1~13 | |

| Density | 1.5 g/cm3 | |