Categories

New products

-

Lens Ring Joint Gasket

If you are willing to import customized and good quality high lumen Lens Ring Joint Gasket from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Lens Ring Joint Gasket price and quotation with a such exporter, providing with Lens Ring Joint Gasket enquiry, welcome to contact us.

-

Double Jacket Gasket

If you are willing to import customized and good quality high lumen Double Jacket Gasket from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Double Jacket Gasket price and quotation with a such exporter, providing with Double Jacket Gasket enquiry, welcome to contact us.

-

Corrugated Gaskets

If you are willing to import customized and good quality high lumen Corrugated Gaskets from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Corrugated Gaskets price and quotation with a such exporter, providing with Corrugated Gaskets enquiry, welcome to contact us.

-

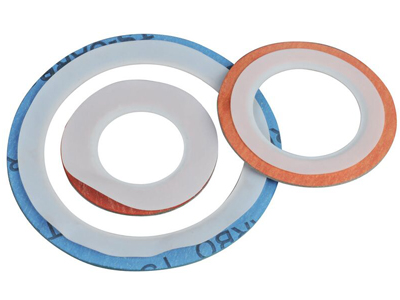

PTFE Envelope Gasket

If you are willing to import customized and good quality high lumen PTFE Envelope Gasket from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM PTFE Envelope Gasket price and quotation with a such exporter, providing with PTFE Envelope Gasket enquiry, welcome to contact us.

-

Rubber Sheet

If you are willing to import customized and good quality high lumen Rubber Sheet from a such manufacturer and supplier, or you are going to check CREE, EMC, CE and OEM Rubber Sheet price and quotation with a such exporter, providing with Rubber Sheet enquiry, welcome to contact us.

Solid material gaskets

HIT:14 DATE:2015/3/25

The idea behind solid material is to use metals which cannot be punched out of sheets but are still cheap to produce. These gaskets generally have a much higher level of quality control than sheet gaskets and generally can withstand much higher temperatures and pressures. The key downside is that a solid metal must be greatly compressed in order to become flush with the flange head and prevent leakage. The material choice is more difficult; because metals are primarily used, process contamination and oxidation are risks. An additional downside is that the metal used must be softer than the flange — in order to ensure that the flange does not warp and thereby prevent sealing with future gaskets. Even so, these gaskets have found a niche in industry.